Silicon crystal growth for semiconductor

SiC crystal growth

Si / SiC / LED epitaxy

MOCVD /CVD

Various equipment for Fab (Oxidizing furnace, RTP etc)

Endeavour makes SiC coating graphite for Si and SiC epitaxy process. The quality of the coating can have direct impact on the performance of wafer's epitaxy layer.

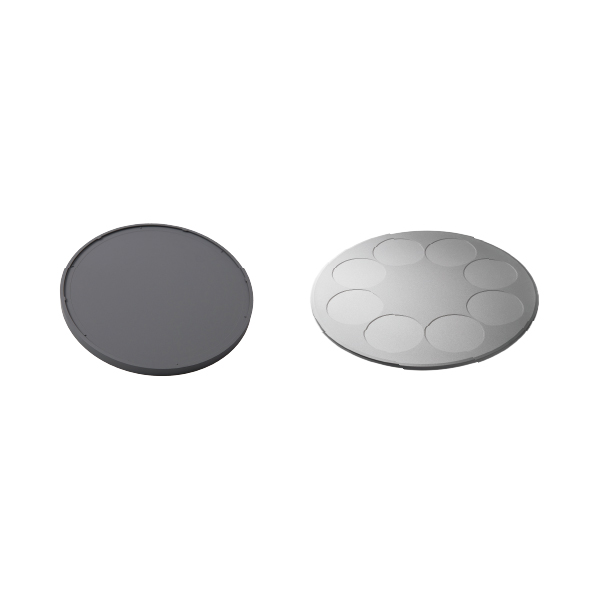

We apply a thin layer of SiC onto the surface of high purity graphite to form a very dense and chemical corrosion resistant coating. Our SiC-coated graphite wafer carrier can offer very high purity, uniform coating and longer service life together with excellent thermal stability properties.

Our graphite material is selected by the right properties for optimal temperature uniformity and fast temperature cycles.

Our high accuracy machining and CVD SiC coating can ensure an optimal performance and extended life of wafer carrier. We can also customize wafer carriers for your different process needs.

Endeavour develops TaC coating for more demanding applications:

-SiC PVT crystal growth

-Epitaxy under more demanding temperature and chemical corrosion condition

We make a high density deposition of poly crystalline TaC coating on the surface of high purity graphite through chemical vapor deposition process. The material can offer much higher performance than SiC coating:

-Thermal stability, enabling working condition of up to 2,400 °C under vacuum, and SiC PVT crystal growth of up to up 2,200°C

-Chemical corrosion resistant capability, enabling working in environment of H2 and NH3 under high temperature

Website: www.endeavour-am.com

Tel: +86(0)512-5240 0868+86-137 6138 9918

Email: sales@endeavour-am.com

Address: 6 Weng Zhuang Road, Shanghu, Changshu City, Jiangsu Province, P.R.China

Copyright ©2024 | Endeavour Advanced Materials (Suzhou) Co., Ltd | All Rights Reserved